February 10, 2025 · 14 min read

The Digital Shift in Oil and Gas: Enhancing Efficiency, Automation, and Sustainability

Shaimaa Badawi

Digital transformation is reshaping the oil and gas industry. As companies adopt AI, IoT, and automation, they face challenges in aligning teams, tracking progress, and ensuring compliance across offshore rigs, refineries, and corporate offices. This article explores how technology is improving meeting efficiency, decision-making processes, and project execution, helping oil and gas enterprises stay ahead in a rapidly evolving industry.

What is digital transformation in the oil and gas industry?

Digital transformation in the oil and gas industry refers to the integration of digital technologies into every aspect of operations, from exploration and drilling to refining and distribution. The goal is to enhance efficiency, reduce costs, improve safety, and support sustainability initiatives. Technologies like IoT, AI, machine learning, cloud computing, and blockchain are driving this transformation, enabling real-time monitoring, predictive maintenance, and data-driven decision-making.

Evolution of digital transformation in oil and gas

1. Early adoption (pre-2000s): Automation and SCADA systems

Oil and gas companies began incorporating automation technologies in the late 20th century with Supervisory Control and Data Acquisition (SCADA) systems. These systems allowed remote monitoring and control of drilling, pipelines, and refineries, reducing manual intervention and improving operational efficiency.

2. Expansion of data-driven decision-making (2000s-2010s): IoT and big data

As sensors and IoT devices became more advanced, oil and gas companies started collecting large amounts of operational data. Big data analytics allowed firms to optimize production, predict equipment failures, and enhance resource management. During this period, digital oilfields became a major focus, using data to maximize asset performance.

3. Advanced AI, machine learning, and cloud adoption (2010s-present)

The past decade has seen rapid advances in artificial intelligence and machine learning. Companies now use AI-driven predictive maintenance to reduce downtime, automate drilling operations, and optimize supply chains. Cloud computing has enabled remote collaboration and real-time analytics, allowing decision-makers to access insights from anywhere.

As industries embrace AI to enhance efficiency, sectors like banking are also undergoing a shift from traditional banking to fintech, leveraging digital advancements to meet evolving customer expectations.

4. The sustainability and ESG era (present-future): Digital-first sustainability initiatives

As the industry faces increasing pressure to reduce its environmental footprint, digital transformation is playing a key role in sustainability efforts. AI-powered monitoring helps companies track emissions, blockchain enhances transparency in carbon trading, and digital twins simulate real-world operations to minimize waste and optimize efficiency.

Key milestones in digital transformation

- Real-time data monitoring: IoT sensors provide continuous insights into asset performance.

- AI-driven automation: Reducing human intervention in high-risk operations.

- Predictive maintenance: Machine learning models forecast failures before they happen.

- Cloud-based collaboration: Breaking down silos and improving cross-functional decision-making.

- Sustainability tracking: AI and blockchain ensure regulatory compliance and carbon reduction.

How is digitalization improving efficiency in oil and gas?

The oil and gas industry operates in complex, high-risk environments where equipment reliability, real-time data, and predictive analytics are critical for efficiency. Three key technologies (IoT, AI-driven predictive maintenance, and digital twins) are revolutionizing the industry by improving operational performance, reducing downtime, and optimizing resource use.

1. IoT: Real-time data for smarter operations

Internet of Things (IoT) refers to a network of interconnected sensors and devices that collect and transmit real-time operational data. In oil and gas, IoT plays a crucial role in monitoring assets, detecting anomalies, and automating processes.

- Real-time monitoring: Sensors track equipment performance, pipeline conditions, and environmental factors.

- Remote asset management: Offshore and remote sites can be monitored without manual intervention.

- Reduced downtime: Early alerts prevent failures before they escalate.

Example: BP uses IoT sensors in its "Plant Operations Advisor," which helps detect equipment anomalies in real time, reducing unplanned shutdowns and optimizing production.

2. AI-driven predictive maintenance: Reducing downtime and failures

Predictive maintenance (PdM) uses AI and machine learning to analyze sensor data and predict equipment failures before they happen. Beyond predictive maintenance, machine learning enhances meeting preparation by automating agenda creation, summarizing past discussions, and aligning meetings with strategic objectives.

Unlike traditional scheduled maintenance, which can be costly and inefficient, predictive maintenance optimizes servicing schedules based on actual equipment conditions.

- Minimizes unplanned outages: AI detects early signs of wear and tear.

- Extends equipment lifespan: Timely maintenance prevents catastrophic failures.

- Optimizes resource allocation: Reduces unnecessary maintenance costs.

Example: Shell implemented AI-driven predictive maintenance for its offshore platforms, reducing downtime by 20% and cutting maintenance costs by $4 million per year.

3. Digital twins: Simulating and optimizing operations

A digital twin is a virtual replica of a physical asset or system, continuously updated with real-time data. This allows operators to test scenarios, optimize performance, and improve decision-making without disrupting actual operations.

- Optimizes production: Simulations reveal inefficiencies in extraction and refining.

- Enhances safety: Engineers can test emergency protocols in a virtual environment.

- Improves energy efficiency: AI-driven models adjust processes to minimize energy waste.

Example: Chevron uses digital twin technology in its refineries to simulate process changes before implementation, leading to 2%–5% gains in operational efficiency.

How is automation transforming upstream, midstream, and downstream operations?

Automation is reshaping the oil and gas industry across upstream, midstream, and downstream operations by improving efficiency, safety, and cost-effectiveness. From AI-driven drilling systems to automated pipeline monitoring and smart refineries, automation reduces human error, optimizes performance, and enhances decision-making.

1. Upstream: Smarter exploration and production

Upstream operations involve exploration, drilling, and extraction of oil and gas. Automation in this phase enhances efficiency by improving drilling precision, optimizing resource use, and minimizing safety risks.

- Automated drilling rigs: AI-powered rigs adjust in real time to optimize speed and reduce downtime.

- AI-based reservoir analysis: Machine learning improves accuracy in detecting viable reserves. Just as AI is refining reservoir analysis, it is also optimizing meeting agendas with AI-powered intelligence, ensuring that discussions remain productive and outcome-driven.

- Remote-operated vehicles (ROVs): Used in offshore drilling to inspect deep-sea operations without human intervention.

- Predictive maintenance: Sensors monitor equipment health, preventing costly failures before they happen.

Example: ExxonMobil uses automated well monitoring systems to track reservoir performance, reducing operational costs by 15%.

2. Midstream: Safer and more efficient transport and storage

The midstream sector includes pipelines, storage, and transportation of crude oil and natural gas. Automation in this phase ensures leak detection, regulatory compliance, and efficient logistics management.

- Automated pipeline monitoring: IoT sensors detect leaks, corrosion, and pressure changes in real time.

- Smart drones for inspection: Reduce manual pipeline surveillance, improving speed and accuracy.

- AI-driven logistics optimization: AI streamlines scheduling and routing, preventing bottlenecks in transportation.

- Automated tank gauging: Monitors oil levels and temperature in storage facilities, reducing manual checks.

Example: Kinder Morgan employs AI-powered leak detection systems to improve pipeline safety and cut response times by 50%.

3. Downstream: Smarter refining and distribution

Downstream operations include refining crude oil, processing natural gas, and distributing fuel to end users. Automation in this phase enhances efficiency, quality control, and sustainability.

- AI-driven refinery optimization: AI models analyze production data to reduce energy consumption and waste.

- Robotic process automation (RPA): Handles repetitive tasks like inventory tracking and compliance reporting.

- Automated blending and mixing: Ensures consistent product quality in fuel processing.

- Digital twin refineries: Virtual replicas optimize refinery performance before making real-world changes.

Example: Shell uses AI-powered refinery optimization, cutting energy use by 10% and reducing emissions.

How are robotics and AI enhancing safety and workforce roles in the oil and gas sector?

The oil and gas industry operates in high-risk environments, where equipment failures, hazardous conditions, and human errors can lead to serious accidents. Robotics and AI are transforming safety protocols and workforce roles by reducing direct human exposure to dangerous tasks, improving risk assessment, and optimizing workforce efficiency.

1. Enhancing safety: Reducing risks in hazardous environments

Robotics and AI-driven systems help prevent accidents, minimize exposure to hazardous conditions, and improve emergency response times.

- Autonomous inspection drones: Drones equipped with AI-powered vision detect leaks, corrosion, and structural weaknesses in offshore rigs, pipelines, and refineries without human intervention.

- AI-powered predictive safety systems: AI analyzes historical accident data to predict and prevent safety incidents.

- Robotic process automation (RPA) for hazardous tasks: Robots handle dangerous operations, such as offshore drilling maintenance, pipeline welding, and deep-sea inspections.

- Smart wearables for workers: AI-powered helmets, smart vests, and exoskeletons monitor fatigue, gas exposure, and physical strain in real time.

Example: BP uses autonomous drones and AI-powered sensors to inspect offshore rigs, reducing human exposure to hazardous sites by 80%.

2. Optimizing workforce roles: Human-machine collaboration

As automation takes over high-risk and repetitive tasks, human roles are shifting toward supervision, advanced analytics, and AI-driven decision-making. Similarly, AI-driven meeting tools help reduce meeting fatigue by automating scheduling, note-taking, and follow-ups, allowing professionals to focus on strategic decision-making.

- Robotics-assisted maintenance: Workers focus on complex problem-solving while AI-driven robots handle routine equipment checks.

- AI-driven training simulations: VR and AI-powered simulations train workers on crisis response without real-world risk.

- Remote operations centers: Engineers and technicians oversee automated oilfield operations from centralized control hubs, reducing the need for on-site personnel.

AI-powered workforce scheduling: AI optimizes staffing levels, ensuring the right personnel are deployed at the right time. AI-powered meeting management tools streamline collaboration, ensuring that the right stakeholders are engaged at the right time for critical decision-making.

3. The future: AI, robotics, and safety innovations

✔ Zero-entry operations: Fully automated robotic systems perform dangerous offshore and refinery tasks without human intervention.

✔ AI-driven emergency response: Machine learning analyzes crisis situations in real time, guiding rapid decision-making.

✔ Collaborative robots (cobots): AI-driven robotic assistants work alongside human workers to improve efficiency and safety.

How can digital transformation help oil and gas companies reduce their carbon footprint?

As the oil and gas industry faces increasing pressure to reduce emissions and comply with stricter environmental regulations, digital transformation has become a key enabler of sustainability. Technologies like AI, IoT, blockchain, and digital twins help companies monitor emissions and optimize energy use.

1. AI-driven emission monitoring

Oil and gas operations produce methane, CO₂, and other greenhouse gases (GHGs). AI-powered monitoring systems analyze real-time emissions data, helping companies identify leaks, optimize fuel usage, and reduce flaring. AI is also shaping stakeholder sentiment analysis in meetings, ensuring decisions align with sustainability goals and corporate strategies.

- Predictive analytics for methane leaks: AI detects early signs of leaks, preventing excess emissions.

- Flare gas reduction: AI optimizes flare stack operations to minimize waste.

- Carbon capture optimization: AI helps maximize the efficiency of carbon capture and storage (CCS) systems.

Example: ExxonMobil uses AI-driven leak detection systems to reduce methane emissions, cutting operational emissions by 25% in key facilities.

2. IoT sensors for environmental compliance

Internet of Things (IoT) devices track environmental parameters in real time, ensuring compliance with emissions regulations.

- Continuous air and water quality monitoring: Smart sensors detect pollutants before they exceed legal limits.

- Automated compliance reporting: IoT platforms generate real-time reports for regulators, reducing human error.

- Remote monitoring for offshore sites: Reduces the environmental risks of transporting inspection crews.

Example: BP’s IoT-powered remote monitoring system has helped reduce inspection-related emissions by 30% in offshore facilities.

3. Digital twins for energy efficiency and sustainable operations

A digital twin is a virtual model of an asset or process, continuously updated with real-world data. By simulating different operational scenarios, companies can identify energy-saving strategies and minimize waste.

- Energy optimization: AI simulations find the most energy-efficient refinery settings.

- Predictive maintenance for emissions control: Prevents faulty equipment from increasing emissions.

- Sustainable drilling strategies: Helps optimize well placement to minimize environmental impact.

Example: Shell uses digital twins in refineries, reducing energy consumption by 10% and lowering CO₂ emissions.

4. Blockchain for transparent sustainability reporting

Blockchain ensures tamper-proof environmental records, increasing transparency in carbon credits, emissions trading, and ESG reporting.

- Carbon credit verification: Ensures companies accurately offset emissions.

- Supply chain traceability: Tracks emissions across operations for full lifecycle accountability.

- Regulatory audit readiness: Prevents compliance fraud with secure digital records.

Example: Oil majors like Chevron and TotalEnergies use blockchain-based carbon tracking systems to enhance transparency in emissions reporting.

What are some successful examples of digital transformation in oil and gas?

Digital transformation is revolutionizing the oil and gas industry, driving efficiency, safety, and sustainability. Companies are leveraging advanced technologies to optimize operations and reduce environmental impact.

Successful examples of digital transformation in oil and gas

1. BP's AI integration with Palantir

BP has entered a five-year partnership with Palantir to utilize artificial intelligence for enhancing decision-making processes. This collaboration involves deploying large language models to autonomously analyze data from BP's operations, providing actionable insights to engineers. This initiative builds upon their decade-long partnership, during which Palantir's technology facilitated the creation of a "digital twin" of BP’s operations, significantly improving performance across various global sites. AI-powered solutions are transforming not only oil and gas but also meeting management, making decision-making more intelligent and strategic through real-time data insights.

2. Tyrion integration's SCADA platform deployment

Tyrion Integration has introduced its Nucleus SCADA platform to the Permian Basin, offering a cost-effective and scalable solution for remote monitoring and automation in oil and natural gas production. Nucleus serves as an all-in-one system with built-in fiber communication, eliminating the need for expensive on-premises infrastructure. This deployment enhances operational efficiency and reduces costs for nearly 1,000 installations in the region.

3. AI-driven production optimization in the Permian Basin

In the Permian Basin of Texas and New Mexico, artificial intelligence has enabled oil companies to increase daily oil production by 60% over the past decade while reducing their workforce by 40%. AI tools assist companies like Exxon Mobil and Chevron in better predicting oil yields, managing equipment remotely, and automating operations, leading to significant efficiency gains and cost reductions.

Emerging technologies shaping the future

1. Carbon capture, utilization, and storage (CCUS)

CCUS technologies are gaining widespread adoption, particularly in regions like North America and Europe. Projects such as Canada’s Quest and Norway’s Northern Lights are setting benchmarks for reducing industrial emissions, aiming to capture and store carbon dioxide to mitigate climate change impacts.

2. Advanced robotics and automation

The integration of robotics and automation is enhancing operational efficiency and safety in the oil and gas sector. Innovations include autonomous inspection drones, robotic process automation (RPA) for hazardous tasks, and AI-driven predictive maintenance systems that reduce downtime and improve safety.

3. Blockchain for transparent sustainability reporting

Blockchain technology ensures tamper-proof environmental records, increasing transparency in carbon credits, emissions trading, and ESG reporting. This innovation helps companies accurately offset emissions, track supply chain emissions, and maintain regulatory compliance.

How can companies measure the ROI of their digital transformation initiatives?

Measuring the ROI of digital transformation in oil and gas is essential for justifying technology investments, optimizing operational performance, and ensuring long-term value creation. Since digital initiatives impact multiple aspects of operations, companies must go beyond financial metrics and assess improvements in efficiency, safety, compliance, and sustainability.

1. Key metrics for measuring ROI in digital transformation

Operational efficiency gains

- Reduction in downtime: Measure improvements from predictive maintenance and AI-driven monitoring. The impact of AI extends beyond industrial applications, with businesses leveraging AI to reduce meeting times and increase ROI, leading to better productivity and efficiency.

- Increased production rates: Assess how automation and real-time data optimize oil and gas extraction.

- Process optimization: Track reductions in drilling time, refining processes, and logistics inefficiencies.

Cost savings and productivity improvements

- Lower maintenance costs: Monitor savings from AI-driven maintenance versus traditional reactive approaches.

- Reduction in workforce-related expenses: Track efficiency gains from automation reducing manual labor needs.

- Supply chain optimization: Measure cost reductions in logistics, procurement, and inventory management.

Enhanced safety and risk mitigation

- Fewer safety incidents: Measure reductions in workplace accidents due to automation and robotics.

- Regulatory compliance costs: Track reductions in fines, penalties, and environmental non-compliance issues.

- Insurance premium reductions: Assess how improved safety protocols lower insurance liabilities.

Revenue growth and business expansion

- New revenue streams: Evaluate income from AI-driven analytics, digital twin services, or carbon offset programs.

- Faster time-to-market: Assess reductions in project cycle times due to automation and digital workflows.

- Market competitiveness: Compare revenue growth against competitors who have not embraced digitalization.

Sustainability and carbon reduction benefits

- Energy efficiency improvements: Measure reductions in fuel consumption through AI-powered optimization.

- Emission reductions: Track CO₂ and methane reductions using digital monitoring solutions.

- Water and resource management: Assess waste reduction and recycling efforts driven by IoT sensors.

2. ROI calculation formula for digital transformation

A simplified way to measure ROI is: ROI (%) = Net benefits from digital transformation − investment cost / investment cost x 100.

Where:

- Net benefits include cost savings, efficiency gains, revenue growth, and sustainability incentives.

- Investment cost includes software, hardware, training, and implementation expenses.

How can adam.ai enhance collaboration in oil and gas enterprises?

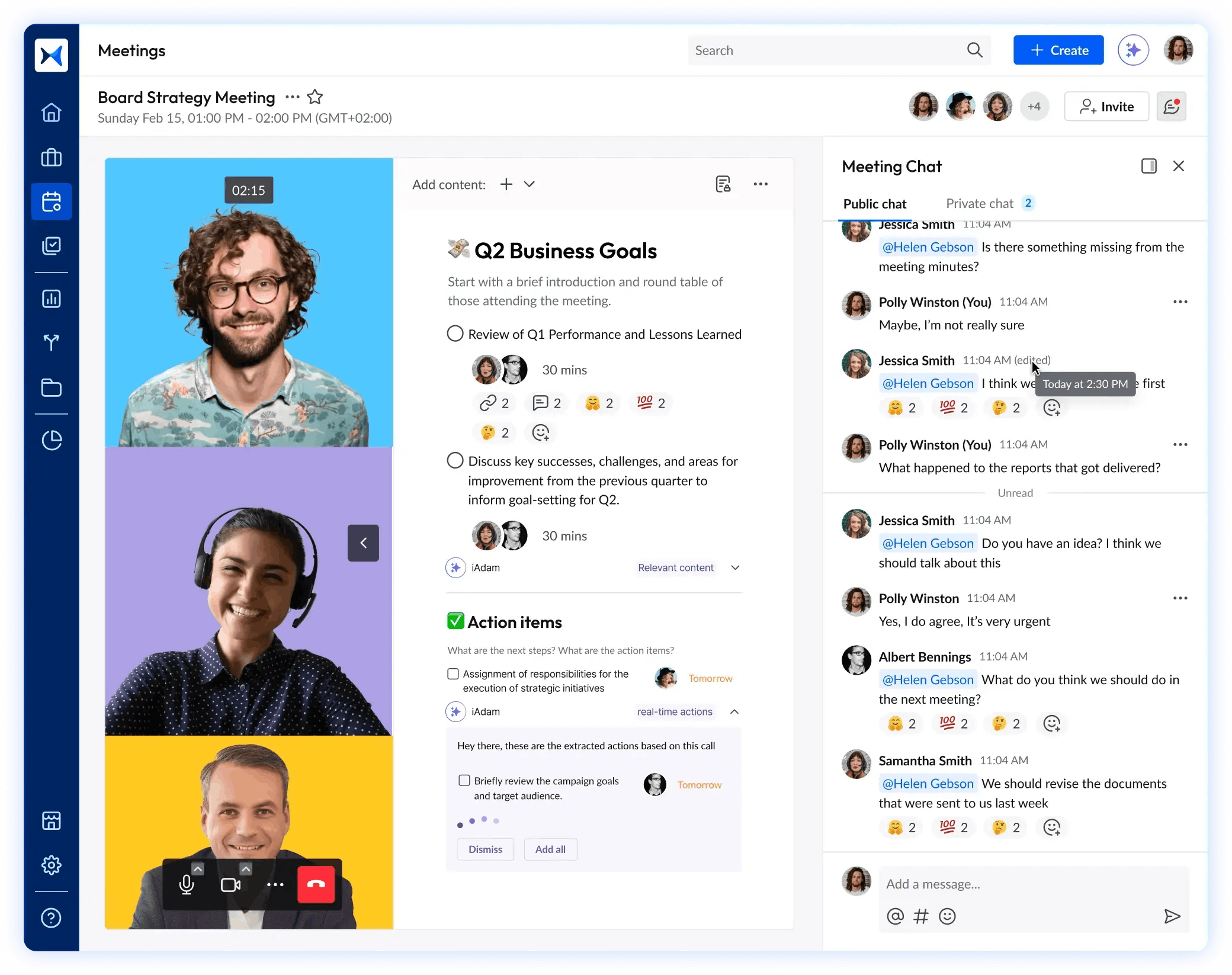

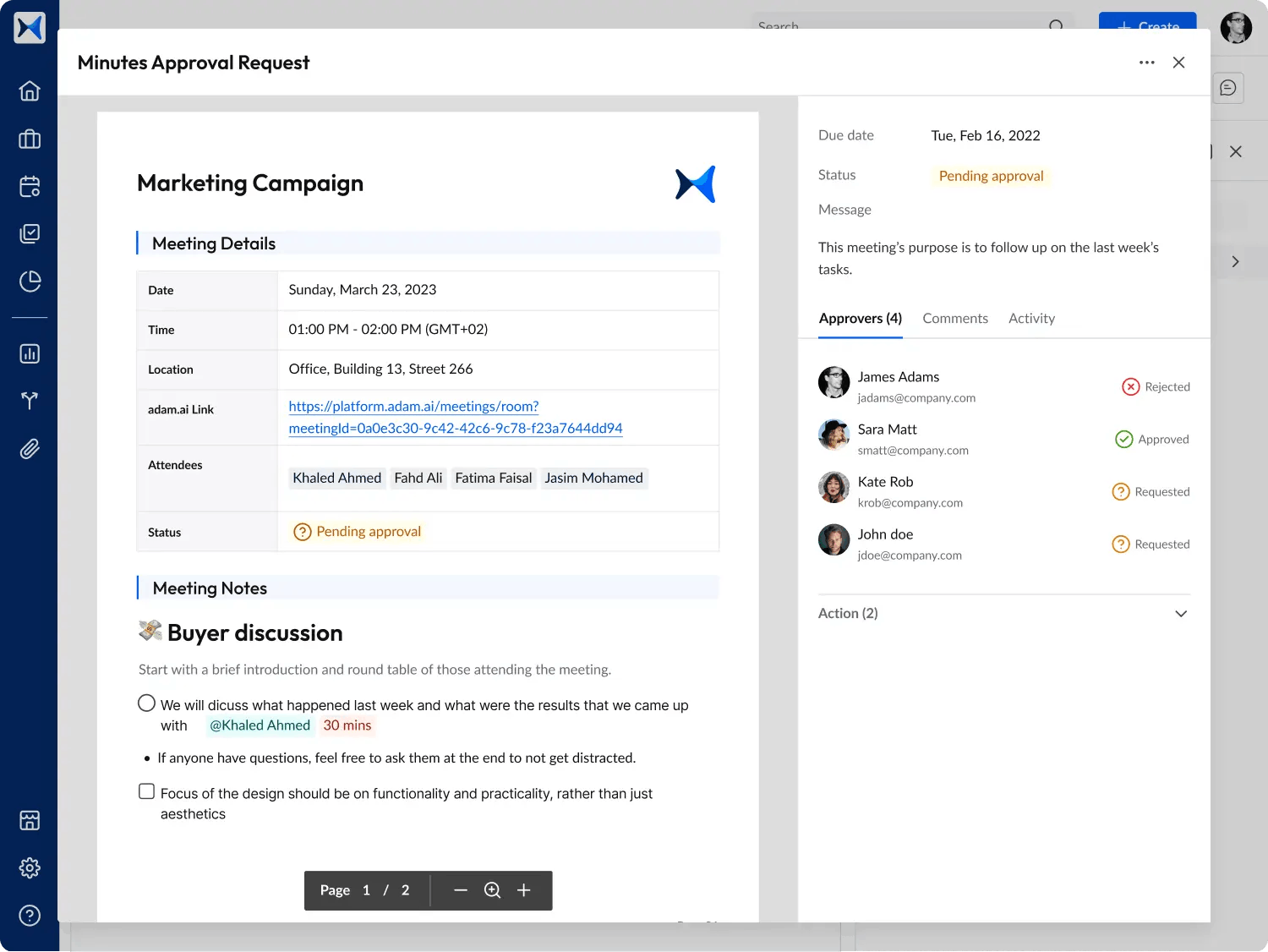

Digital transformation in oil and gas depends on efficient collaboration, structured decision-making, and streamlined project execution. adam.ai helps enterprises achieve these goals by ensuring meetings drive action, decisions are well-documented, and project execution remains on track.

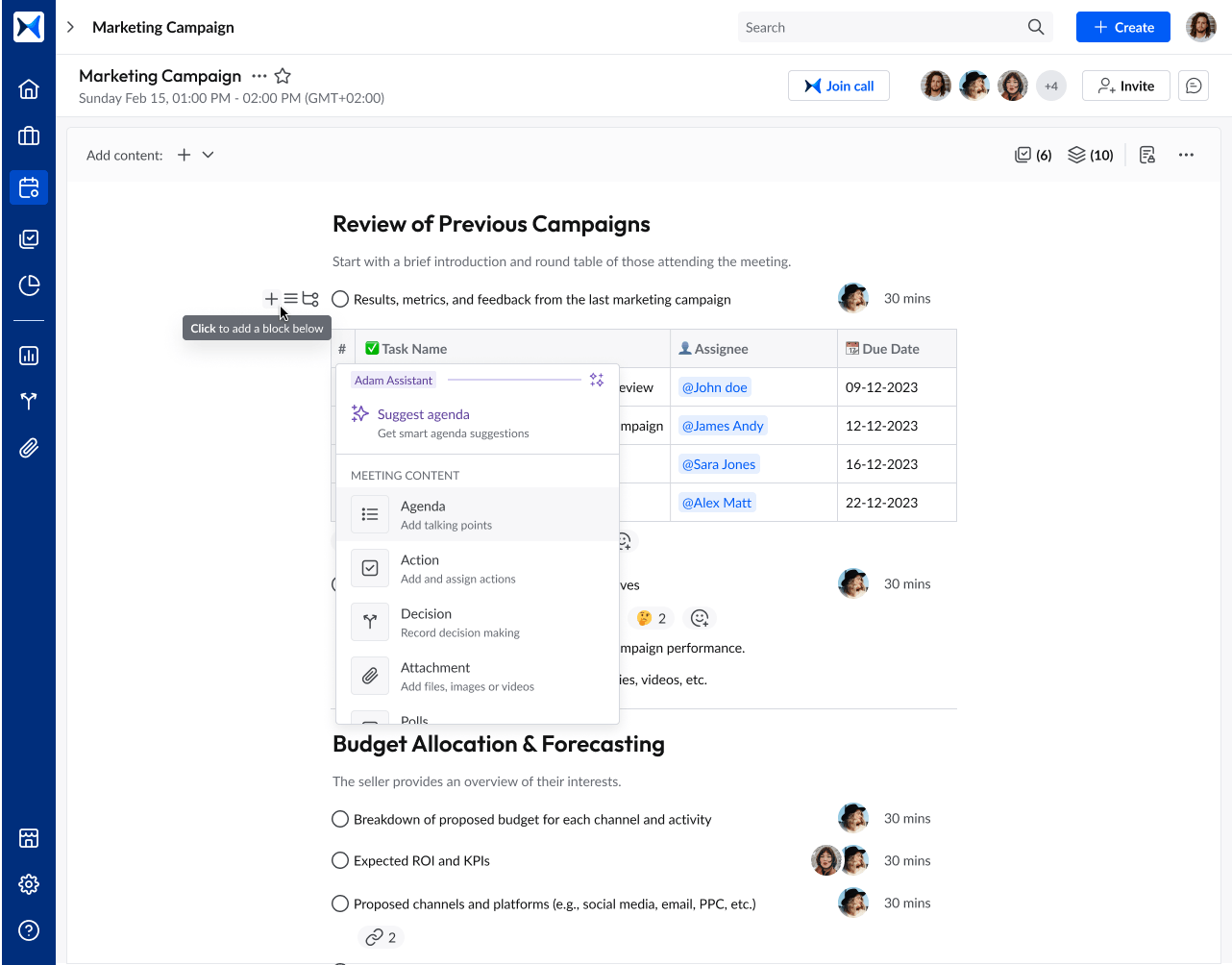

- Agenda management: Stay on track with AI, IoT, and automation projects by structuring your meetings with clear topics, assigned time slots, and strategic objectives.

- Content collaboration: Attach, share, and reference compliance documents, real-time analytics, and strategic plans directly in your meetings.

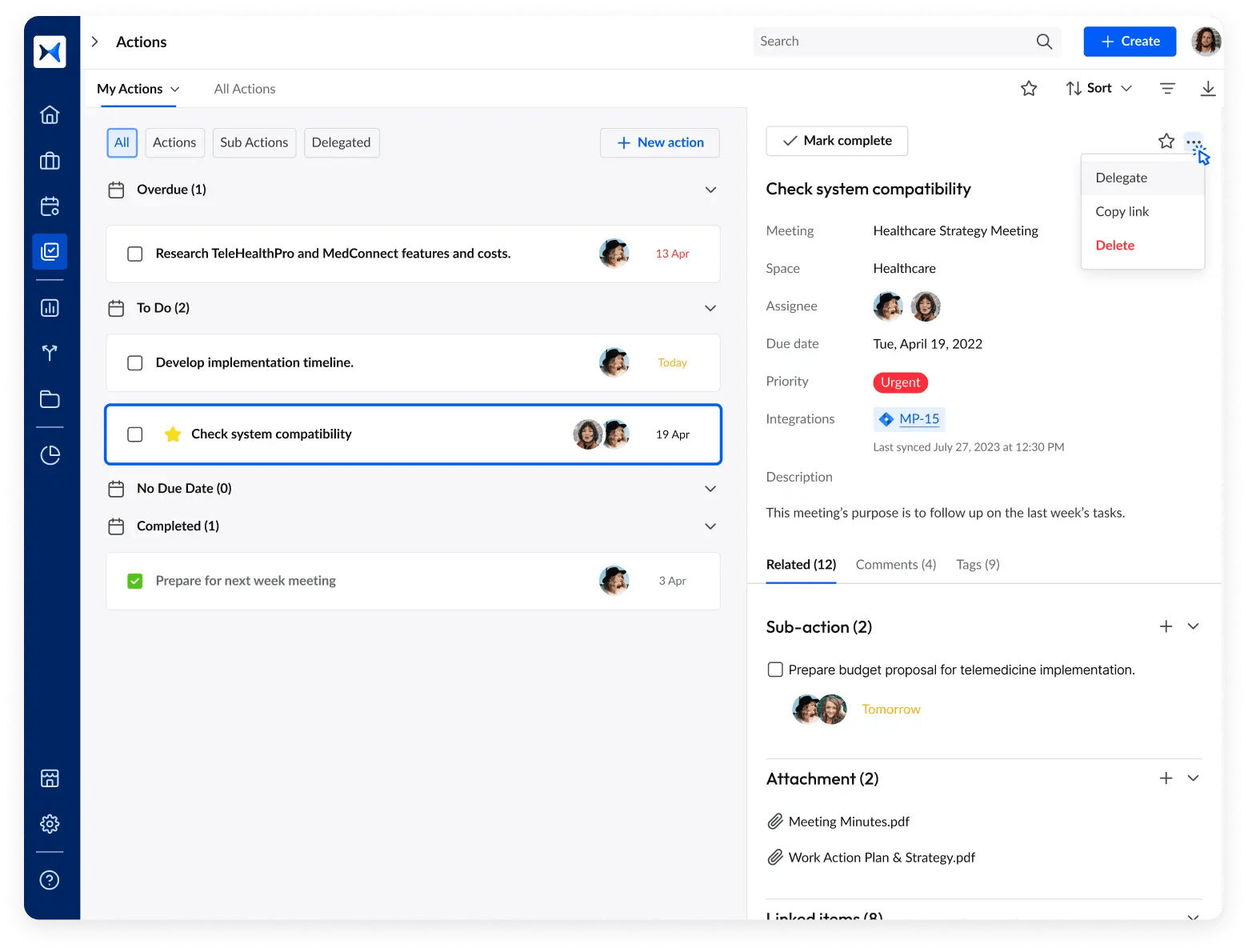

- Action management: Ensure that pipeline automation, predictive maintenance, and digitalization projects stay on schedule. Assign tasks, set deadlines, and track progress effortlessly.

- Meeting minutes: Never lose track of critical decisions. adam.ai automatically records and organizes your meeting minutes, creating a reliable audit trail for compliance, sustainability initiatives, and operational strategy.

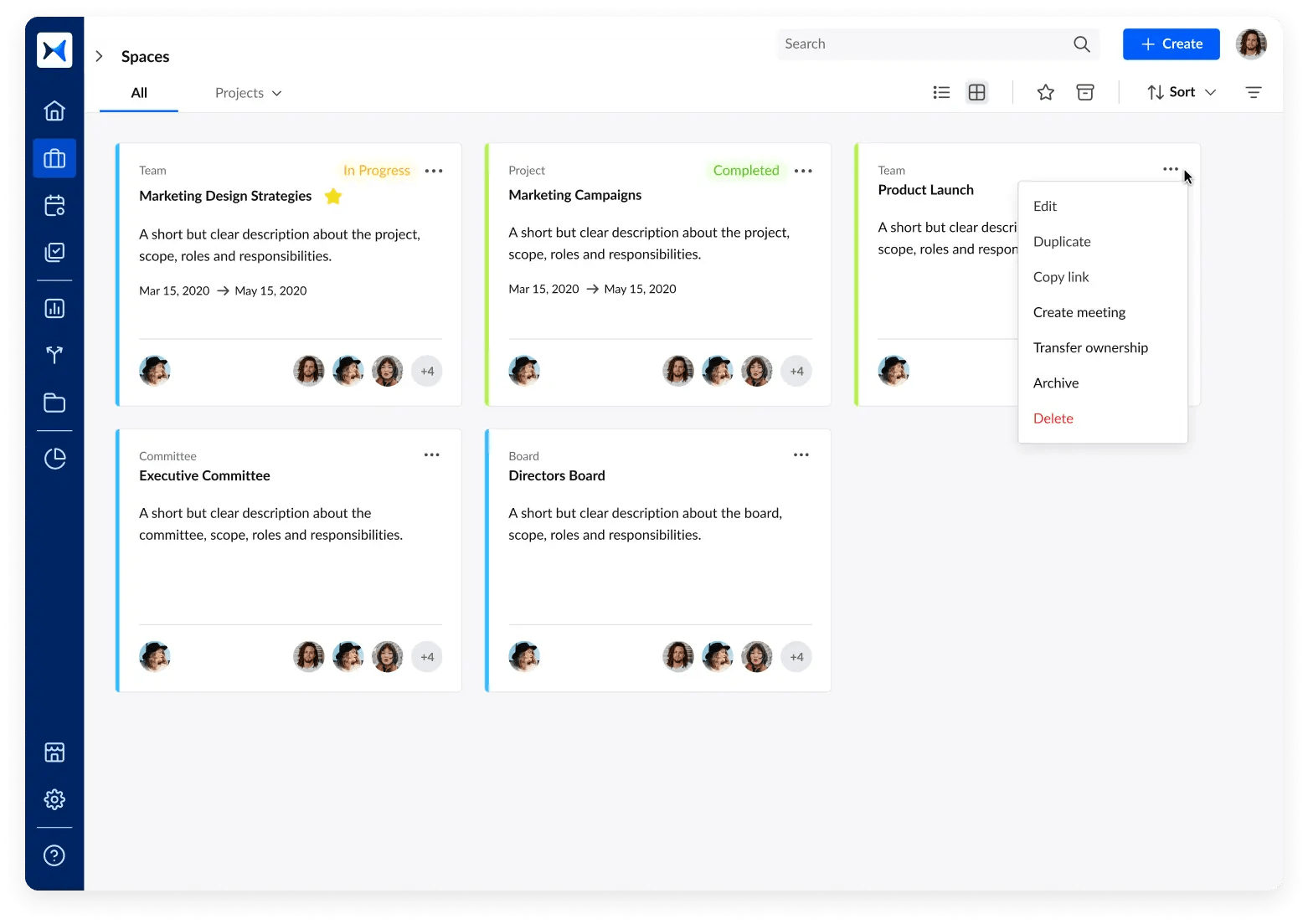

- Multi-space management: Operate efficiently across offshore rigs, refineries, and corporate offices by keeping everything organized in one place. You can track different projects, teams, and initiatives without losing visibility.

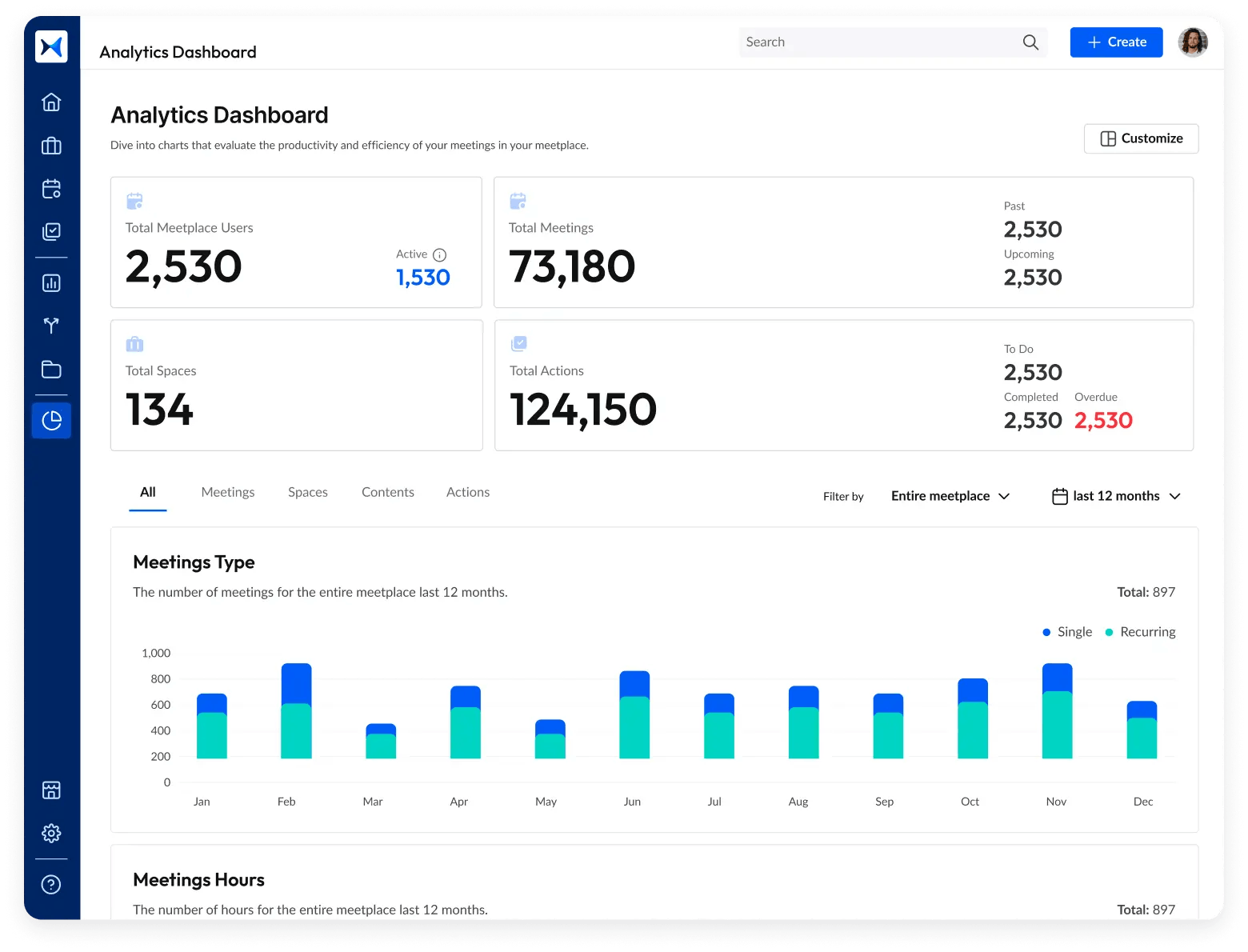

- Analytical dashboards: Monitor your meeting performance across the organization with adam.ai’s analytics dashboards. Track key metrics, action completion rates, and overall progress to make data-driven decisions and report on business outcomes.

Transform how you conduct critical meetings—From meticulous preparation to effective execution and insightful follow-up, adam.ai integrates comprehensive analytics, full customization, and intuitive interfaces with powerful meeting management tools.

Easy onboarding. Enterprise-grade security. 24/7 dedicated support.

The bottom line

Digital transformation is redefining oil and gas operations, improving efficiency, safety, and sustainability. To make technology-driven changes truly effective, enterprises need a structured approach to collaboration, decision-making, and project execution. That’s where intelligent meeting management platforms play a vital role.

And while there may be multiple solutions available, here is why adam.ai is the meeting management software platform you can trust:

- adam.ai is one of Atlassian Ventures' portfolio companies.

- In the meeting management software category on G2, adam.ai has been ranked a leader and a high performer for successive quarters in the past years.

- adam.ai has been included in the Forrester Report in the AI-enabled meeting technology landscape.

- adam.ai is trusted and used by powerful teams and organizations worldwide for all types of critical meetings, like board, committee, project management, and business development meetings.

- And most importantly, adam.ai integrates with your existing workflow, is SOC2 compliant, provides dedicated support and success, and has a free trial option.

Subscribe to adam.ai blog

Stay ahead with the latest insights—get our newest blog posts, tips, and updates sent straight to your inbox.